Inventory and Production Manager

Flowchart for the Inventory and Production Manager, illustrating relationships to production activities.

As an affordable add-on to SDScribe™, we offer the Inventory and Production Manager, a powerful tool for inventorying raw materials, parts, and finished products. Create production batches that allocate against stock of ingredients and parts. Prepare batch sheets for the production floor. Generate reorder reports and purchase orders.

Features and functionality

Inventory

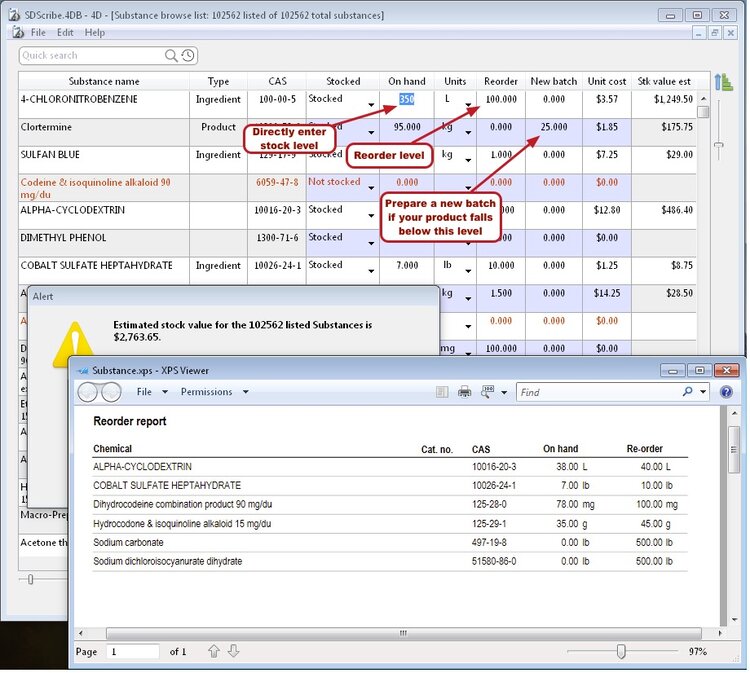

- Maintain inventories of ingredients, containers, labels, and finished product.

- Quick inventory enables you to set initial stock levels for parts and ingredients, using a spreadsheet-style listing.

- Withdraw ingredients, bottles, caps, labels, etc. from inventory as you allocate them to a specific batch. SDScribe™ automatically converts between warehouse stock units and batch units as necessary, and warns when stock levels are insufficient to produce a batch.

- Place the product from a batch into finished goods inventory.

- Set reorder levels for parts and ingredients, and generate reorder reports.

Substance browse list: quick entry mode for inventory, reorder report

Production

- Create a batch by entering ingredients, parts, instructions, and quality control parameters. You can also record notes and photos.

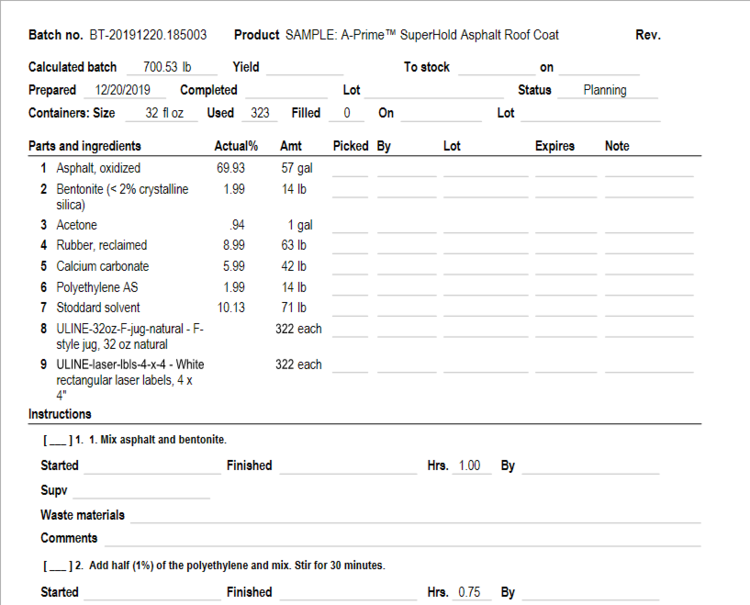

Batch entry form: items tab, for entering ingredients and parts, and calculating batch sizes/costs.

- Or create a batch from components in a mixture. Just right-click on a row representing a mixture in the Substances browse list, and select "Create batch from this Substance" in the contextual menu.

Substance browse list: creating a batch from a Substance record.

Or duplicate an existing batch. Create one or more complete duplicates from a previous batch. Re-naming a duplicated batch permits you to have different recipes for product variations.

Design knockout experiments with duplicate batches that each remove one ingredient. An ingredient is designated as the solvent, and the program automatically calculates the concentrations for the other ingredients.

Batch browse list: duplicating an existing batch as a knockout experiment (resulting in 13 additional batches).

- Generate batch sheets (BOMs) for the workers to use during production. Workers can enter time spent on each instruction.

Sample batch sheet (2021 format, larger fonts)

Generate container labels in a full-featured word processing area.

Calculate per-bottle costs (including parts, ingredients, labor, and markup) of a production run.

Maintain lot numbers, task duration, spillage, bottles filled, analytical results, pictures, and notes with each batch.

View volatiles/VOC calculations for paints and inks. You just enter the percent solids, volatiles, etc. for batch ingredients in the Substances section.

SDScribe™ performs calculations in the background as you enter ingredients and their amounts: total batch size, number of containers required, ingredient concentrations, and costs.

Purchase orders

- Generate purchase orders by selecting the parts or ingredients.

Selecting items for a purchase order

General

- Part of SDScribe™. No need to install more software.

- One Year email support included at no extra charge